Compression Testing My Kawasaki Z650 - No Electric Starter

In my ongoing project to get my old 1978 Kawasaki Z650 properly back on the road, it is definitely a case of "three steps forward, two steps back".

Having identified and cured a huge volume of issues, including multiple carburettor rebuilds and replacing o-rings that had been destroyed by modern ethanol-based fuel, I thought it would finally be ready to road test.

I discovered it wasn't. The bike ticks over fine, but when I put it in gear and let the clutch out, it fluffs and dies. There are a large number of possible causes, most of them inter-related and hard (or expensive) to diagnose. Many of them are things I think I have already sorted out - ignition, coils, battery, timing, fuel feed etc. The most likely remaining causes are either an air leak somewhere in the inlet manifold system, or a compression issue.

So I decided to compression test first, as I've already got everything I need to do that.

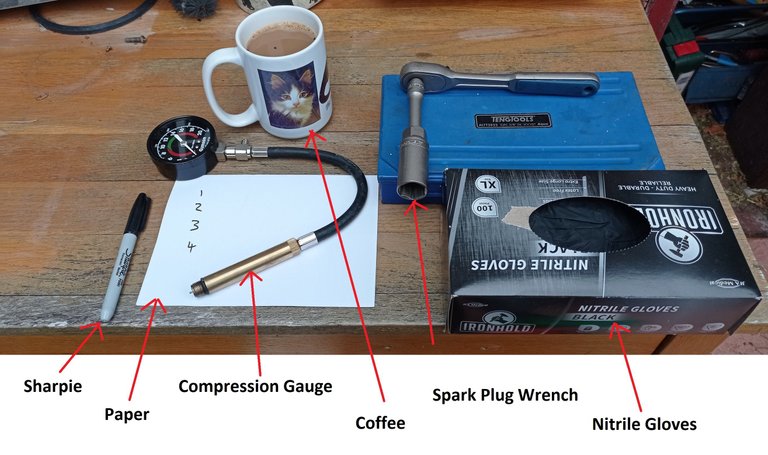

My first job with anything I do on the bike is to get all the tools I think I'll need together and lay them out ready. It saves a huge amount of time going through tool boxes and spare parts crates in the middle of the job !

Below is a photo of what's needed for this one;

As you can see, the most important tool of all takes centre stage. Coffee, and lots of it ! It's in my favourite mug, an over-sized one I bought a few years ago to help fund the medical care of a very special internet cat 😀

With that done, I needed to get the bike up to a normal running temperature. I'd done a compression test a few months ago, but subsequently discovered I'd done it wrong. It had been done cold (which couldn't be helped, the bike wouldn't start at all at that stage), but also I'd left the plugs in and kept the throttle closed. The plugs aren't too much of an issue apart from making it harder to do the test, but keeping the throttle closed would have restricted airflow into each cylinder.

The photo below shows the bike ticking over at about 1250 RPM, just to prove it really does run, however imperfectly ! The manual says tickover should be 950-1050, but the bike has never liked ticking over that low.

One of the big issues with doing a compression test is that almost all the online guidance expects you to have an electric start and to be able to turn the engine over on it.

The electric starter is one of the few real weak points on the Z650's. On the three engines I've had, none of them have ever had the starter motor work properly (or at all), and many friends over the years who have had Zeds have had the same problem, although they seem to have got it sorted out by the time they made the F model (which had quite a few significant engine updates).

But there is a solution. You just have to be fit. The process looks like this;

- Remove all spark plugs.

- Screw the compression gauge into the cylinder to be tested, and press the pressure release to ensure it's zeroed.

- Holding the throttle fully open and with the ignitions switched off, use the kick-starter to turn the engine over as rapidly as possible until compression gauge reaches as high as it's going to. Since I'm unable to see the dial most of the time, experiments have shown that it gets to it's highest reading after about 15-20 kicks. So I give it 25, just to be sure.

- Make a note of the reading. If in doubt, repeat the process to ensure consistent results.

- Repeat steps 3 & 4 for each cylinder.

So that's a minimum of 100, and more likely 200, kicks. Leg like an elephant, me !

Below is the gauge screwed into cylinder #1. This is the bit of the process that makes me the most nervous. The dial flops around uncontrollably on it's thick rubber hose, creating a high risk of paintwork damage and/or cross-threading the spark plug thread.

While I was doing all this, I checked the condition of the spark plugs themselves. All four were similar to the photo below; sooty but not massively fouled. That's to be expected when the bike has been running static with the choke on a lot recently. But the fact that all four were virtually identical is a good sign, if one was different it would be a cause for investigation.

The manual quotes that standard compression should be 156-185 PSI, with a lower service limit of 114 PSI and less than 14PSI between cylinders.

Below are photos of three of the 4 cylinders, 1, 3 and 4 in that order (cylinder 2 was a bit too blurry to use).

As can be seen, the readings aren't great. On the other hand, they aren't awful either. The two inner cylinders (2 & 3) were just under 150 PSI, while both the outer two (1 & 4) were at around 125 PSI.

There are a number of factors to consider. First, the manual assumes a relatively new bike that has been running regularly, not an old one which has run intermittently. Second, it assumes compression testing using a working electric starter. Hah, the chance would be a fine thing ! Finally, the outer two cylinders are going to drop in temperature the fastest which would open up tolerances.

However, I'm still not hugely happy with the results, and it tells me my next job needs to be to repeat the test. This time, I need to put a teaspoon of engine oil in each bore just before doing it, which should help to narrow the problem down to whether the piston rings or valve clearances need to be investigated.

I should probably check the valve clearances anyway, but that's a subject for another post.....

!LUV

!LOL

lolztoken.com

The stock market.

Credit: reddit

@alonicus, I sent you an $LOLZ on behalf of zakludick

(6/6)

Delegate Hive Tokens to Farm $LOLZ and earn 110% Rewards. Learn more.

You did a good job even though you’re not really satisfied with what you have done

I’m glad you could give it a good try

See you next time!

Wow big bro, it's still looking good anyways...The details and effort you put into the process are very very impressive. Even though the results weren't perfect, it's clear you're making progress man. Keep up the great work and can't wait to see the next steps bro

Greetings @alonicus ,

Thank you for such a detailed post on something so very technical...happy to see your very meticulous approach to discovery of what the source of the problem could possibly be.

Kind Regards,

Bleujay

Thank you ! It's just a case of trying to be slow and methodical, although I'm looking forward to the day I can ride it without wondering how far I'll have to push it home 😁